Color Concrete

- No Mess on the jobsite

- The most vibrant pigment with the highest tinting strength

- Produces more intense colors than liquid.

- Achieves consistent results.

- No buckets to buy or bags to disintegrate in the mix.

- Produce any manufactures color on the market.

- Custom colors available.

- Prepackaged granular color pigment (25lb bags or job specific quantities)

- Do-it Yourself pigment

- Color Hardener

- Color Release

- Sealers

- Surface retarder

-

What is integral concrete color?

It is color (made from iron oxide pigments) that is added to the concrete when it is being made, either in a ready-mix plant or onsite in a ready-mix truck. The color is evenly dispersed throughout and integrated into the concrete. The entire batch of concrete will be evenly colored inside and out.

One major advantage of integrally colored concrete is that if it chips or is damaged, it is much less noticeable because the concrete is colored all the way through.

-

Does integral color fade?

No. Iron oxide pigments cannot fade. Concrete, however, can change over time with exposure to the environment (weather, sun, foot or wheeled traffic, etc.). To reduce the effects of wear on concrete, it is important to use a durable mix design, an experienced concrete finisher and a high-quality concrete sealer that is suitable for the specific application (e.g., driveway, patio, garage, etc.). Colored concrete can be refreshed by power-washing and resealing the surface.

-

Is integral color difficult to use?

Not at all. Creter Concrete makes it easy with our automated granular pigment dispenser. Concrete arrives at your job ready to pour However, we strongly recommend using a skilled and experienced concrete finisher. Finishing techniques will affect the final color, so it is important to use a qualified contractor.

-

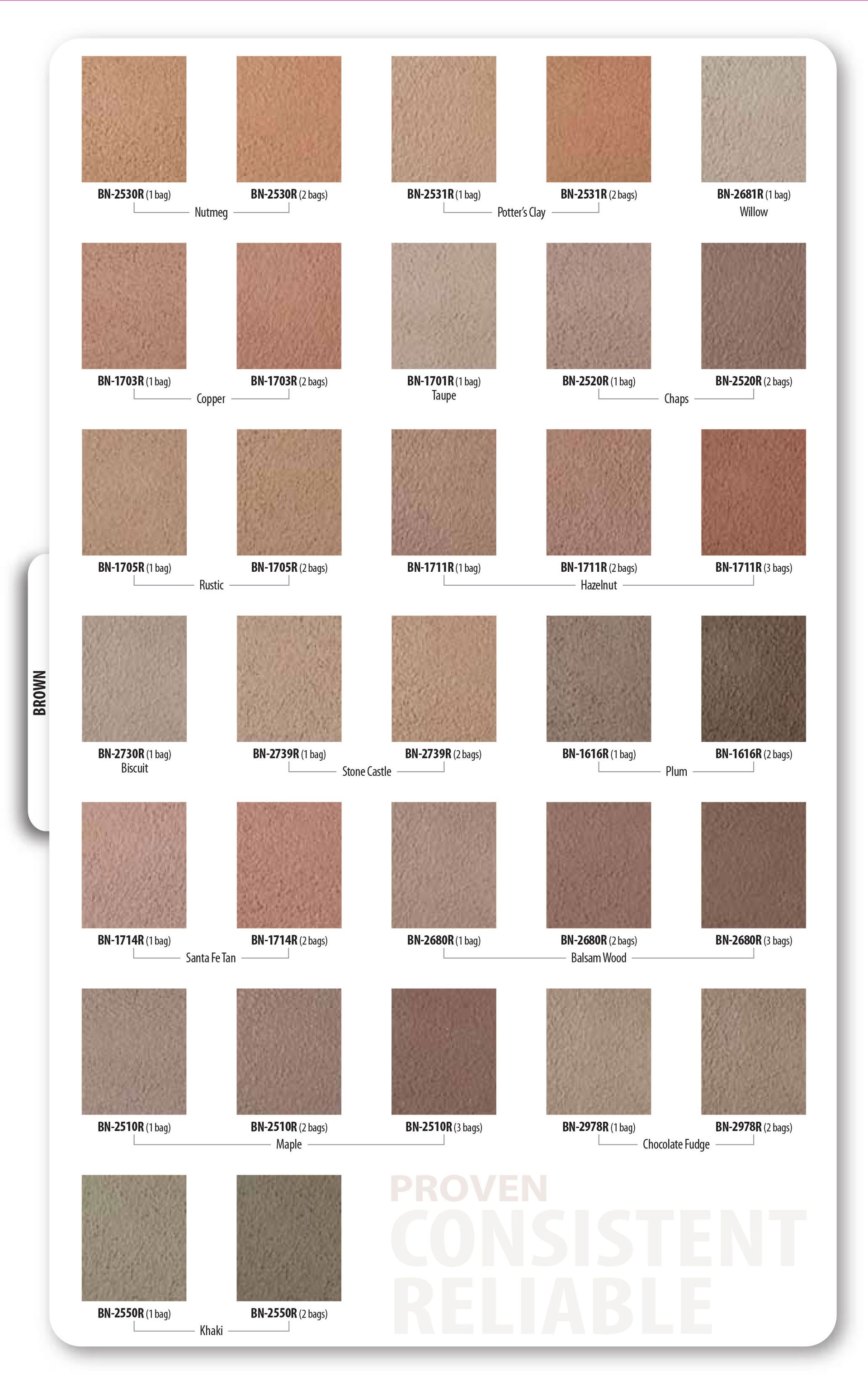

Will the color I choose look exactly like the swatch on the color chart?

No. Concrete is a unique material – no two pieces are the same. The color of concrete –even plain concrete – is affected by many, many factors such as: cement powder and sand color; aggregate color and size; the amount of water used; and finishing methods. Even though our dispenser calibrates every color swatch to an actual colored concrete sample to try to make our color charts as accurate as possible, it might not be an exact match to your concrete. We highly recommend pouring a mock-up to be sure you can achieve the desired color with the raw materials and finishing techniques you will be using.

-

My colored concrete was poured a week ago and it is much darker than the color I chose. Is there a problem?

No, this is perfectly normal. It takes at least 30 days for all the moisture to evaporate from freshly poured concrete. During this time, the color will continue to lighten. Some areas may even appear lighter than others due to faster evaporation. Wait at least 30 days before the final color inspection.

-

Should colored concrete be sealed?

Yes. Even though concrete is extremely durable, it is still susceptible to the environment. A high-quality sealer should be applied at least 30 days after the concrete has been poured. Please keep in mind that some sealers will impart a color, and most will slightly darken the color. Always test it in an inconspicuous place before applying to the entire surface.

-

I received my order of integral color, and it looks different than the color I chose. Is the dry pigment representative of the final color?

No. The dry color is not reflective of the final result. It must be mixed with concrete. We create our color charts using photos of actual samples of colored concrete.

-

Are air-entraining admixtures compatible with integral color?

Yes

-

Do admixtures affect colored concrete?

They can, but consistency is the key to mitigate their effects. The same admixture(s) should be used at the same dosages throughout a given job. In fact, every component of the mix design must be the same throughout a pour to help ensure consistent color. Calcium chloride accelerators should NEVER be used in colored concrete.

-

What happens if I pour colored concrete on separate days?

There could be color differences, which is why pouring on different days should be avoided, if possible.

-

Can I just add pigment to the surface of the concrete and mix it in?

No. Integral color must be added to the mix BEFORE pouring and placing the concrete.

-

I saw a color from another supplier that isn’t on your color chart, can you produce it?

Yes, our unique computerized dispenser has color recipes for multiple pigment manufacturers. Please provide our sales staff with the manufacture, color name and color # when ordering.

-

Do you offer prepackaged bags?

Yes, if you would like to purchase color for a jobsite out of our delivery area, we can provide you with prepackaged color to add at your jobsite.

-

Why is the price for integral concrete different for each color?

Unfortunately, there is no set pricing for color. There are a few factors that change the cost of producing your desired color, Cement content and the amount of pigment used to produce desired color changes from mix to mix. Please contact our sales staff @ 908 788 3288 x1 for pricing

-

I would like to match an existing concrete color; can you match it?

It is difficult to match existing concrete, but not impossible. Our staff can take samples and send away to a color lab to analyze and come up if a formula that will come close to your existing slab.

We’re able to service all of the areas in and around central New Jersey due to our innovative computer-assisted dispatching system which allows for seamless radio communication to our vehicles.

Our drivers are certified and well trained to deliver Redi-Mix Concrete in a timely and professional manner.

We are here to help!

For orders and questions:

Contractor / Homeowner by phone: 908-782-3288 (Ext 1)

By email: Sales@CreterConcrete.com